Ukukhetha ilungeloI-hex bolt kanye namantongomanekubalulekile ekuqinisekiseni ukuphila isikhathi eside kwemishini yokwakha. Ukukhetha okungalungile kungaholela ekusabalaliseni komthwalo wentambo ongalingani, njengoba kuqokonyiswe ucwaningo lukaMotosh, oluhlonze izinto ezithambile zamantongomane njengento enomthelela. Ukuhlolwa kokukhathala kwe-Kazemi kuphinde kwembula ukuthi ukulayishwa kwe-multi-axial kunciphisa kakhulu ubude besikhathi sokuphila kwebhawodi, kugcizelela ukubaluleka kwento kanye nomklamo. Izinsimbi ezisezingeni eliphezulu, njengelima ibhawodi namantongomane, ithrekhi ibhawudi namantongomane, nomaingxenye yebhawudi namantongomane, vimbela ukwehluleka njalo, ukonga izindleko ngokuhamba kwesikhathi. Ukukhetha okufanele kuthuthukisa ukuqina, kunciphisa ukunakekelwa, futhi kukhulisa ukusebenza ezindaweni ezidinga kakhulu.

Okuthathwayo Okubalulekile

- Ukukhethaimpahla efanele yamabhawudinamantongomane abalulekile. Insimbi engagqwali imelana nokugqwala kahle, kuyilapho i-carbon steel ishibhile futhi iqinile.

- Ukwazi imikhawulo yomthwalo kuyisihluthulelo sokuphepha. Ngaso sonke isikhathi khetha izinto zokubopha ezihlangabezana noma ezeqa umthwalo odingekayo womsebenzi wakho wokwakha.

- Usayizi olungile kanye nohlobo lwentambo kwenza ukuxhumana okuqinile. Sebenzisa amashadi osayizi namathuluzi afana namarula ukuze uhlole izilinganiso ngaphambi kokuwasebenzisa.

- Ukuthengaama-fasteners ekhwalithi enhleyonga imali ngokuhamba kwesikhathi. Izinto eziqinile zidinga ukulungiswa okuncane futhi zigcina okokusebenza kusebenza isikhathi eside.

- Ukuhlola izinsimbi ngokuvamile kusiza ukugwema izinkinga. Bheka umonakalo, ukugqwala, namandla afanele okulayisha ukuze ugcine amathuluzi akho okwakha ephephile.

Ukukhetha Okubalulekile kwe-Hex Bolt ne-Nut

Izinto Ezivamile Nezakhiwo Zazo

Ukukhetha impahla efanelekubhawodi le-hex namantongomane kubalulekile ukuze kuqinisekiswe ukuqina nokusebenza ezinhlelweni zokwakha. Impahla ngayinye inikezela ngezakhiwo ezihlukile eziyenza ifanele ukusetshenziswa okuthile. Ngezansi ukuqhathaniswa kwezinto ezisetshenziswa kakhulu:

| Okubalulekile | Izinzuzo | Ukubi |

|---|---|---|

| Insimbi engagqwali | Ukumelana nokugqwala okuhle kakhulu; ilungele izicelo zangaphandle nezasolwandle | Kubiza kakhulu kunezinsimbi ezivamile |

| Insimbi Yekhabhoni | Iqinile futhi ihlala isikhathi eside; kuqiza kahle | Ingase idinge izimbotshana zokuvikela ukugqwala |

| I-Titanium | Isilinganiso esihle kakhulu samandla nesisindo; ilungele izindawo ezeqisayo | Izindleko eziphakeme; kungenzeka ingasetshenziswa kabanzi |

Insimbi engagqwali igqama ngokumelana nokugqwala, okuyenza ilungele izindawo zangaphandle nezasolwandle. I-Carbon steel, ngakolunye uhlangothi, iyindlela engabizi kakhulu enikeza amandla nokuqina kodwa ngokuvamile idinga ukumbozwa okwengeziwe ukuvimbela ukugqwala. I-Titanium, nakuba ingajwayelekile kangako, inikeza isilinganiso esikhethekile samandla nesisindo, okuyenza ifanelekele izimo ezimbi kakhulu.

Ukuqonda lezi zakhiwo kusiza ekukhetheni izinto ezifanele kakhulu zebhawodi le-hex namantongomane, ukuqinisekisa ukuthi izinsimbi zihlangabezana nezidingo zendawo yokwakha.

Ukukhetha Okubalulekile Kwendawo Ethize

Indawo lapho kuzosetshenziswa i-hex bolt namantongomane kuba nomthelela omkhulu ekukhetheni izinto. Kuzinhlelo zokusebenza zangaphandle noma zasolwandle, insimbi engagqwali ivamise ukuba yisinqumo esikhethwayo ngenxa yongqimba lwe-oxide oluvikelayo oluvimbela i-oxidation nokugqwala. Lesi sici sithuthukisa ukuphila kwaso isikhathi eside futhi sinciphisa izindleko zokuyilungisa ngokuhamba kwesikhathi.

Ezimweni ezishisa kakhulu noma ezinolaka lwamakhemikhali, insimbi ye-alloy enembozo yempushana emnyama isebenza kahle kakhulu. I-coating ayigcini nje ngokuthuthukisa ukumelana nokugqwala kodwa futhi yandisa ukuqina kwezinga lokushisa, ikwenze ifaneleke izicelo ezifunayo. Ngezinjongo zokwakha okuvamile, i-carbon steel isalokhu iyinketho ethandwayo ngenxa yokufinyeleleka kwayo nokuguquguquka, nakuba ingase idinge ukufakwa kukaphethiloli noma i-zinc plating ukuze kuvikeleke okwengeziwe.

Ithiphu: Hlala ucabangela izimo zemvelo, ezinjengomswakama, izinga lokushisa, nokuchayeka kumakhemikhali, lapho ukhetha izinto ezisetshenziswayo zamabhawodi e-hex namantongomane. Lokhu kuqinisekisa ukuthi ama-fasteners agcina ubuqotho nokusebenza kwawo ngokuhamba kwesikhathi.

Izinzuzo Zensimbi Engagqwali, I-Carbon Steel, ne-Alloy Steel

Impahla ngayinye inikeza izinzuzo ezihlukile ezihlangabezana nezidingo ezahlukene zokwakha:

- Insimbi engagqwali: Yaziwa ngokumelana nokugqwala okukhethekile, insimbi engagqwali ingaphezu kuka-30% yazo zonke izinto zokubopha ezisetshenziswa ekwakheni. Isilinganiso sayo esiphezulu samandla nesisindo sivumela izakhiwo ezilula, ukunciphisa ukusetshenziswa kwezinto kanye nomthelela wemvelo. Ukwengeza, ukuqina kwayo kuholela ezindlekweni zokunakekela eziphansi, okwenza kube ukukhetha okubiza kakhulu ngokuhamba kwesikhathi.

- Insimbi Yekhabhoni: Le nto isetshenziswa kabanzi ekwakhiweni ngenxa yamandla ayo kanye nokufinyeleleka kwayo. Ilungele izinhlelo zokusebenza lapho izindleko ziyinkinga kodwa amandla angeke abekwe engcupheni. Ngezingubo ezifanele, izinsimbi ze-carbon steel zingakwazi ukumelana nezimo ezinzima, ziqinisekise ukuphila isikhathi eside.

- I-alloy Steel: Ihlinzeka ngezakhiwo ezithuthukisiwe zemishini, insimbi ye-alloy ilungele izinhlelo zokusebenza ezifunayo. Yakhohigh tensile futhi isivuno amandlayenze ifanele imishini esindayo kanye nezingxenye zesakhiwo. Ukuklanywa kwamantongomane amade kuzinsimbi zensimbi ye-alloy kunciphisa ingcindezi emicu, okwandisa amandla okuxhumana nokuzinza.

Ngokuqonda izinzuzo zalezi zinto zokwakha, ochwepheshe bezokwakha bangenza izinqumo ezinolwazi ezithuthukisa ukusebenza nokuphila isikhathi eside kwemishini yabo.

Ukuhlola Amandla kanye Nomthamo Womthwalo

Ukuqonda Izilinganiso Zomthwalo

Izilinganiso zomthwalo zinquma amandla amakhulu i-hex bolt kanye namantongomane angamelana ngaphandle kokwehluleka. Lezi zilinganiso zibalulekile ukuze kuqinisekiswe ukuphepha nokwethembeka kwempahla yokwakha. Onjiniyela babala izilinganiso zomthwalo ngokusekelwe kuzinto ezifana namandla wento ephathekayo, usayizi webhawodi, nomklamo wentambo. Kuzinhlelo zokusebenza zokwakha ezisindayo, izinsimbi kufanele zihlangabezane nezidingo ezithile zobufakazi nobulukhuni ukuze kusingathwe ukucindezeleka okukhulu.

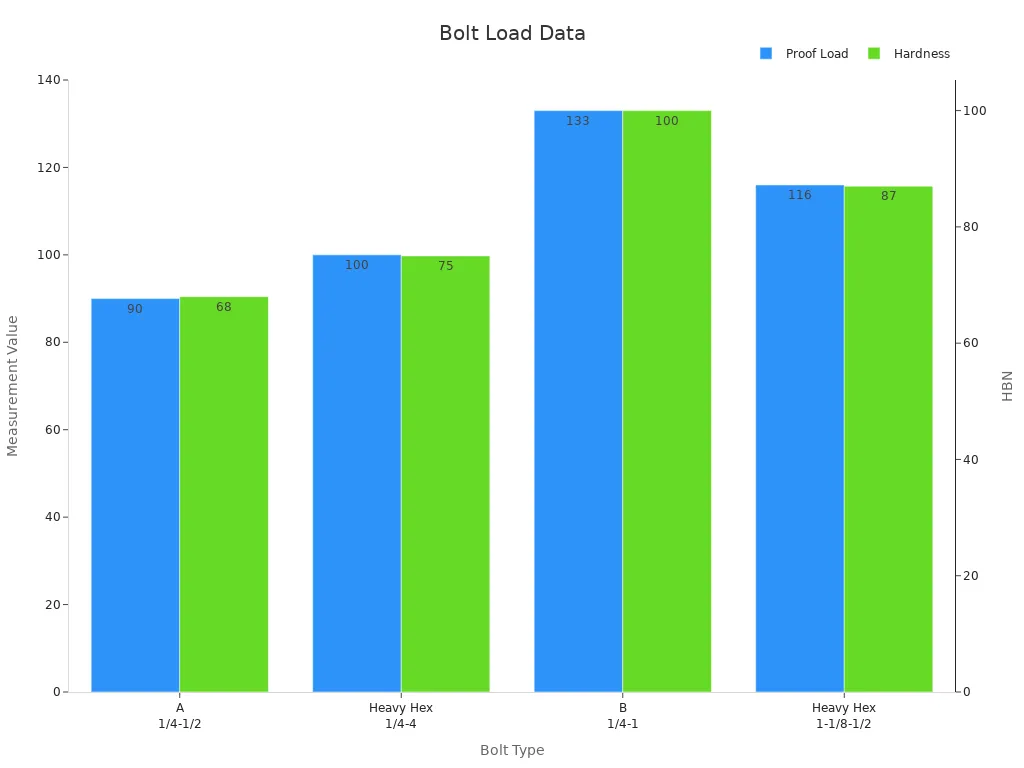

Ithebula elingezansi ligqamisa umthwalo wobufakazi kanye nedatha yobulukhuni yamabanga ahlukahlukene nezitayela zamabhawodi we-hex namantongomane:

| Ibanga | Isitayela | Usayizi (in.) | Umthwalo Wobufakazi (ksi) | Ukuqina (HBN) |

|---|---|---|---|---|

| A | Hex | 1/4 – 1-1/2 | 90 | 68 |

| Heavy Hex | 1/4 – 4 | 100 | 75 | |

| B | Heavy Hex | 1/4 – 1 | 133 | 100 |

| Heavy Hex | 1-1/8 – 1-1/2 | 116 | 87 |

Qaphela: Amantongomane we-hex asindayo aminyene kunamantongomane e-hex ajwayelekile, ahlinzeka ngamandla omthwalo wobufakazi obuphakeme ngokwezindinganiso ze-ASTM A563.

Ukuqonda lezi zilinganiso kusiza ochwepheshe bezokwakha ukuthi bakhethe izixhumi ezihambisana nezidingo zomshini zezinto zabo, okuqinisekisa ukuqina nokuphepha.

Amazinga Omkhakha Wezinto Zokuzibopha Ezinamandla Aphezulu

Amazinga emboni adlala indima ebalulekile ekuchazeni ukusebenza nokuthembeka kwezibophelelo eziphezulu. Lawa mazinga aqinisekisa ukuvumelana ekukhiqizeni futhi anikeze amabhentshimakhi okuhlola amandla aqinile, ubulukhuni, nokuqina. Ngezansi amanye amazinga abalulekile amabhawodi e-hex namantongomane asetshenziswa ekwakheni:

| Okujwayelekile | Incazelo | Amandla Okuqina Aphansi |

|---|---|---|

| I-A354-17e2 | Amabhawudo ensimbi acinyiwe futhi aqinile, ama-Studs, kanye nama-Fasteners | N/A |

| F2882/F2882M-17 | Izikulufu Zensimbi Yengxubevange, Zilashwe Ukushisa | 170 ksi / 1170 MPa |

| F3125/F3125M-25 | Amandla Aphakeme Amabhawodi kanye Nemihlangano | 120 ksi, 144 ksi, 150 ksi / 830 MPa, 1040 MPa |

| F3043-23 | I-twist Off Type Tension Control Structural Bolt Assemblies | 200 ksi |

| F3111-23 | I-Heavy Structural Bolt/Nut/Washer Assemblies | 200 ksi |

| I-F3148-17a(2024) | I-High Strength Structural Bolt Assemblies | 144 nxa |

Lawa mazinga, afana ne-ASTM F3125 ne-F3043, aqinisekisa ukuthi izibophelelo zihlangabezana nezidingo zemishini zezinhlelo zokusebenza ezisindayo. Ochwepheshe bezokwakha kufanele bahlale beqinisekisa ukuthobela la mazinga lapho bekhetha izinto zokubopha zamaphrojekthi abalulekile.

Izicelo Ezidinga I-High-Strength Hex Bolts Namantongomane

Amabhawodi we-hex namantongomane anamandla aphezulu abalulekile ezinhlelweni lapho kukhona imithwalo esindayo nezimo ezimbi kakhulu. Lawa ma-fasteners asetshenziswa kakhulu ku:

- I-Structural Steel Connections: Amabhawodi anamandla aphezulu avikela imishayo namakholomu ezakhiweni nasemabhulohweni, aqinisekisa ukuzinza ngaphansi kwemithwalo enamandla.

- Imishini Enzima: Izinto zokusebenza ezifana nezimba kanye nama-cranes zithembele kuzibopheli ezihlala isikhathi eside ukuze zibhekane nengcindezi yokusebenza nokudlidliza.

- Izimboni zezimboni: Izinsiza ezinezinga lokushisa eliphezulu noma izindawo ezibolayo zidinga izibophelelo ezenziwe ngensimbi yengxubevange noma insimbi engagqwali ukuze kusebenze okuthuthukisiwe.

- Ukwakhiwa Kwasolwandle: Izibophelelo zensimbi engagqwali zimelana nokugqwala endaweni enamanzi anosawoti, zizenze zilungele amadokhu namapulatifomu asogwini lolwandle.

Ishadi elingezansi libonisa ubudlelwano phakathi komthwalo wokuqinisekisa nobulukhuni bamabhawodi ahlukahlukene, ligcizelela ukubaluleka kokukhetha isibopheli esilungile sezinhlelo zokusebenza ezithile:

Ukukhetha i-hex bolt nenati elifanele lalezi zinhlelo zokusebenza kuqinisekisa ukuphila isikhathi eside nokuphepha kweizinto zokwakha. Ochwepheshe kufanele bacabangele izilinganiso zomthwalo, amazinga emboni, kanye nezici zemvelo ukuze benze izinqumo ezinolwazi.

Ukucaciswa kosayizi nochungechunge

Ukukhetha usayizi olungile wezisetshenziswa zokwakha

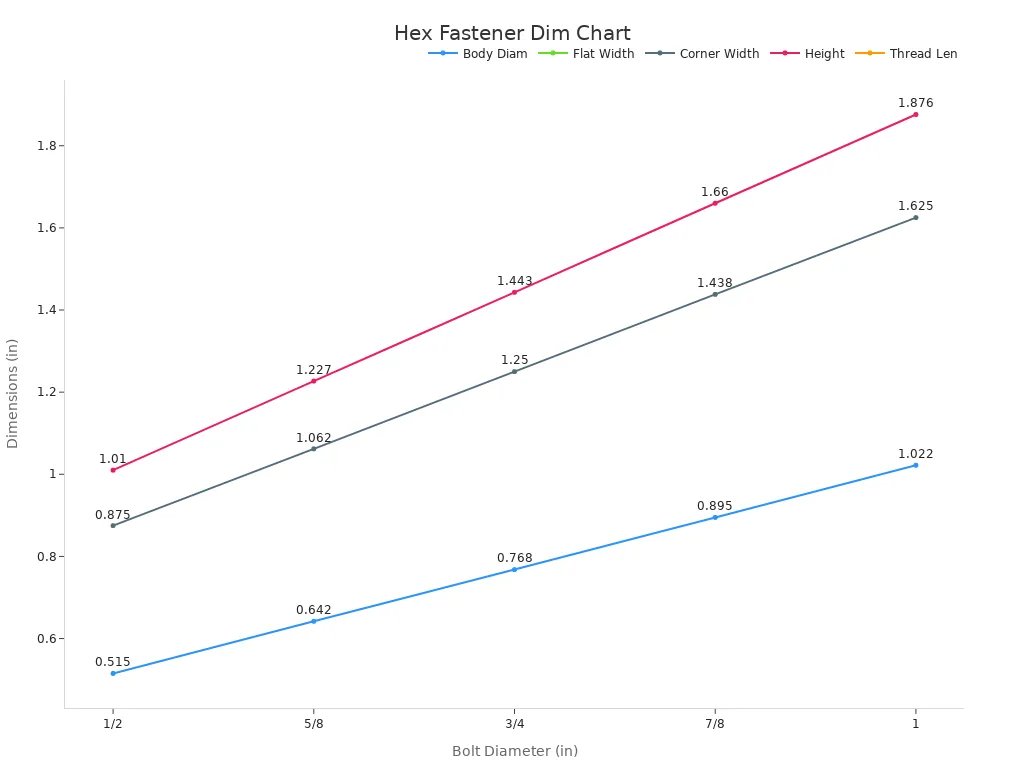

Ukukhetha usayizi olungile webhawodi le-hex namantongomane kubalulekile ukuze kuqinisekiswe ukuxhumana okuphephile nokuthembekile ezintweni zokwakha. Usayizi uthinta ngokuqondile ikhono lesibophelelo lokusingatha imithwalo nokugcina ubuqotho besakhiwo. Amashadi anobukhulu nedatha yokubekezelela inikeza isiqondiso esibalulekile sokukhetha usayizi ofanele. Ithebula elingezansi libonisa ubukhulu obuyinhloko be-hex fasteners:

| I-Bolt Diameter | Ububanzi Bomzimba | Ububanzi Ngaphesheya KwamaFlathi | Ububanzi Ngaphesheya Amakhona | Ubude | Ubude Bomucu |

|---|---|---|---|---|---|

| 1/2 | 0.515 | 7/8 | 0.875 | 1.010 | 5/16 |

| 5/8 | 0.642 | 11/16 | 1.062 | 1.227 | 25/64 |

| 3/4 | 0.768 | 11/4 | 1.250 | 1.443 | 15/32 |

| 7/8 | 0.895 | 17/16 | 1.438 | 1.660 | 35/64 |

| 1 | 1.022 | 15/8 | 1.625 | 1.876 | 39/64 |

Ithiphu: Hlala ubheka amashadi anobukhulu ukuze uqinisekise ukuthi isigcinasi esikhethiwe sifana nezidingo zamathuluzi.

Ukucatshangelwa kwe-Thread Pitch kanye ne-Fit

Iphimbo lentambo nokulinganadlala indima ebalulekile ekusebenzisaneni kwamabhawodi e-hex namantongomane. Ukuphakama kochungechunge kubhekisela ebangeni eliphakathi kwemicu, kuyilapho ukulingana kunquma ukuthi ibhawodi namantongomane kubambana kuqine kangakanani. Ukungafani kwephimbo lochungechunge kungaholela ekubopheni okungafanele, kunciphisa amandla oxhumano. Emishini yokwakha, izintambo ezimahhadla zivame ukuthandwa ngenxa yokumelana kwazo okuphezulu nokukhumula kanye nokuhlanganisa kalula.

Ishadi elingezansi libonisa ubudlelwano phakathi kobubanzi bebhawodi nobukhulu bochungechunge, lisiza ochwepheshe ukuthi bakhethe okulungile kwezinhlelo zabo zokusebenza:

Ukulinganisa nokufanisa ama-Hex Bolts namantongomane

Izilinganiso ezinembile zibalulekile ekufaniseni amabhawodi e-hex namantongomane. Ukusebenzisa amathuluzi afanele kuqinisekisa ukulingana okufanele futhi kuvimbela ukwehluleka kwemishini. Amathuluzi anconyiwe afaka:

- Ama-Calipers: Kala ububanzi, ubude, nosayizi wekhanda ngokunemba.

- I-Thread Gauge: Nquma ukuphakama kwentambo ukuze uqinisekise ukuhambisana.

- I-ruler noma i-Tape Measure: Kala ngokushesha ubude bawo wonke amabhawodi.

Ukulinganiswa kwalawa mathuluzi kubalulekile ukuze kugcinwe ukunemba. Amathuluzi abalwa njalo anciphisa amaphutha, aqinisekise ukuthi izixhumi ziyahlangabezana nokucaciswa okudingekayo.

Ithiphu ye-Pro: Njalo qinisekisa izilinganiso ngaphambi kokufaka ukuze ugweme izixhumi ezingafani, ezingafaka engozini ukuphepha kwemishini.

Ama-coatings kanye Nokuqedwa Kokuqina

Ukubaluleka Kokumelana Nokugqwala

Ukumelana nokugqwala kudlala indima ebalulekile ekwandiseni isikhathi sempilo yezinsimbi ezisetshenziswa emishinini yokwakha. Izici zemvelo ezinjengomswakama, ukushintshashintsha kwezinga lokushisa, nokuchayeka kumakhemikhali kungasheshisa ukuwohloka kwezinsimbi. Izibophelelo ezigqwalile zilimaza ubuqotho besakhiwo semishini, okuholela ekuhlulekeni okungase kube khona kanye nokulungiswa kwezindleko. Ukukhethaama-coatings ahlinzeka ngokuvikeleka kokugqwala okusebenzayoiqinisekisa ukuthi izinto zokubopha zigcina amandla nokusebenza kwazo ngokuhamba kwesikhathi.

Isibonelo, ezindaweni ezingaphandle, izinto zokubopha zivame ukuchayeka emvuleni, umswakama, nezinto ezingcolisayo. Ama-coatings asebenza njengesithiyo sokuzivikela, esivimbela i-oxidation kanye nokwakheka kokugqwala. Lokhu kubaluleke kakhulu kubhawodi le-hex namantongomane, njengoba lezi zingxenye zibalulekile ekubambeni ndawonye imishini esindayo nezakhiwo. Ngokubeka phambili ukumelana nokugqwala, ochwepheshe bezokwakha banganciphisa izidingo zokunakekela futhi bathuthukise ukwethembeka kwemishini.

Ukuqhathanisa I-Zinc Plating, Galvanization, kanye Nezinye Izindwangu

Izingubo ezihlukene zinikeza izinzuzo eziyingqayizivele futhi zifanele izicelo ezithile. Ithebula elingezansi ligqamisa izici ezibalulekile kanye nokusetshenziswa kwama-coatings ajwayelekile:

| Uhlobo Lokumboza | Izici Eziyinhloko | Izinhlelo zokusebenza |

|---|---|---|

| Zinc Coatings | Ukuvikela ukugqwala komhlatshelo, ukumelana komoya okuhle kakhulu, ukonga | Ezezimoto, Ezokwakha, Izinto Ezisindayo |

| I-Phosphate Coatings | Isithiyo esimelene nokugqwala, sithuthukisa ukunamathela kukapende, ukumelana nokugqokwa okumaphakathi | Izingxenye ezidinga ukucutshungulwa okwengeziwe noma ukuqedwa, lapho ukunamathela kopende kubalulekile |

Izingubo ze-Zinc zinikeza ukuvikelwa komhlatshelo, okusho ukuthi ziyagqwala esikhundleni sesibophelelo, ngaleyo ndlela andise isikhathi saso sokuphila. Lokhu kubenza balungele ukwakhiwa okujwayelekile kanye nemishini esindayo. Izembatho ze-phosphate, ngakolunye uhlangothi, zakha isithiyo ngokumelene nokugqwala futhi zithuthukise ukunamathela kopende, okuzenza zifanelekele izingxenye ezidinga ukuqedwa okwengeziwe.

Uma kuqhathaniswa i-zinc plating kanye ne-galvanization, amamethrikhi okusebenza aveza umehluko omkhulu ekuqineni. Izindwangu ezifakwe kahle zingahlala iminyaka engaphezu kwengu-50 ezindaweni zasemaphandleni kanye neminyaka engama-20 kuya kwengama-50 ezindaweni zezimboni. I-Zinc Plating, nakuba ibiza kakhulu, ingase ingasebenzi kahle ezimeni ezinzima ezifana nezindawo zasolwandle, lapho umswakama ophezulu nosawoti kusheshisa ukugqwala. Izinto ezinjengokuqina kwe-coating, ukuchayeka kwemvelo, nezinqubo zokunakekela nazo zithonya impilo ende yalezi ziphetho.

Izindleko Zokulinganisa kanye Nekhwalithi

Izinzuzo Zesikhathi Eside Zokuzibopha Ezisezingeni Eliphezulu

Ukutshala imali kuama-fasteners aphezuluinikeza izinzuzo ezibalulekile zesikhathi eside zemishini yokwakha. Ukuhlolwa komjikelezo wokuphila (LCA) nokuhlaziywa kwezindleko kubonisa ukuthi izibophelelo zeprimiyamu zinciphisa izindleko zesondlo nezokusebenza ngokuhamba kwesikhathi. Isibonelo, izinto zokubopha ezisetshenziswa kumafomu okhonkolo afaka insulating (ama-ICF) zifaka isandla ekwehliseni izindleko zamandla kanye nokuqina okuthuthukisiwe. Nakuba izindleko zokuqala zezibophelelo zekhwalithi ephezulu zingase zibonakale ziphakeme, ikhono lazo lokumelana nokuguga nokucindezeleka kwendawo ezungezile kunciphisa isidingo sokushintshwa njalo. Lokhu kuqina akugcini nje kongi imali kodwa futhi kunciphisa isikhathi sokungasebenzi, kuqinisekisa ukuthi imisebenzi yokwakha ihlala ihleliwe. Ngaphezu kwalokho, isigaba sokusebenza sempahla yokwakha singaphezu kwama-90% omthelela wawo kwezemvelo. Ngokukhetha izinto ezithembekile, ochwepheshe bangathuthukisa ukusimama ngenkathi befinyelela ukusebenza kahle kwezindleko.

Ukugwema Izinketho Ezisezingeni Eliphansi, Ezingabizi

Izibophelelo ezingabizi kakhulu zivame ukubonakala zikhanga ngenxa yokukwazi ukuzithengela, kodwa zingaholela ezinkingeni ezibalulekile. Lezi zibophelelo ngokuvamile azinawo amandla nokuqina okudingekayo ezinhlelweni zokusebenza ezinzima. Ngokuhamba kwesikhathi, zingase zigle, zixege, noma zehluleke ngaphansi kwengcindezi, zibeke engcupheni ukuphepha nokusebenza kwemishini yokwakha. Ukushintsha njalo nokulungiswa okuhlobene nezibophelelo zekhwalithi ephansi kwandisa izindleko zizonke futhi kuphazamise ukusebenza. Ukwengeza, izinto ezisezingeni eliphansi zingaholela ekusabalaliseni komthwalo ongalingani, okusheshisa ukuguga ezingxenyeni zemishini. Ochwepheshe kufanele babeke phambiliizinga phezu kwezindlekoukugwema lezi zingibe futhi uqinisekise impilo ende yemishini yabo.

Izinketho Ezingabizi Zezinto Zokwakha Ukuphila Kade

Izixazululo ezingabizi kakhulu azisho njalo ukukhetha inketho eshibhe kakhulu. Kunalokho, zibandakanya ukukhetha izinto zokwakha nezinqubo ezilinganisa ukufinyeleleka nokusebenza. Izinhlolovo zezimakethe zigqamisa amasu ambalwa okuthola le bhalansi:

- Ukulungiswa kabusha kwemishini kwandisa isikhathi sokuphila kwemishini, kunciphisa isidingo sokukhiqiza okusha.

- Ukuthuthukisa imishini emidala kuthuthukisa ukusebenza kahle kwamandla futhi kwehlisa ukusetshenziswa kukaphethiloli.

- Ukugaywa kabusha kanye nokulahlwa ngendlela efanele kwezinto kukhuthaza ukuphathwa kukadoti kanye nokusimama.

- Ukuthola izinto ezibophezelayo kuqinisekisa ukuqina ngaphandle kokubeka engcupheni izingqinamba zebhajethi.

Ngokwamukela lezi zinqubo, ochwepheshe bezokwakha bangathuthukisa isikhathi eside semishini yabo ngenkathi begcina izindleko zisebenza kahle. Ukukhetha i-hex bolt namantongomane alungile, isibonelo, kuqinisekisa ukusebenza okuthembekile futhi kunciphisa amathuba okuhluleka okungalindelekile.

Ukugwema Amaphutha Avamile

Ukuvimbela Izinto Ezingafani

Ukusebenzisaizinto ezingafaningoba amabhawodi e-hex namantongomane angaholela ekugugeni ngaphambi kwesikhathi, ukugqwala, noma ukwehluleka. Ochwepheshe bezokwakha kufanele baqinisekise ukuhambisana kwezinto ezibonakalayo ukuze kugcinwe ubuqotho bezinsimbi. Isibonelo, ukubhanqa ibhowudi yensimbi engagqwali ne-carbon steel nut kungabangela ukugqwala kwe-galvanic, ikakhulukazi ezindaweni ezinomswakama noma zasolwandle. Lokhu kwenzeka lapho izinsimbi ezimbili ezingafani zihlangana, zidale ukusabela kwe-electrochemical.

Ukuvimbela ukungafani, ochwepheshe kufanele:

- Qondanisa izinto ezinokumelana nokugqwala okufanayo.

- Qinisekisa amabanga nezinto ezibekiwe ngaphambi kokufaka.

- Sebenzisa izinhlanganisela ezinconywe ngumkhiqizi ukuze usebenze kahle.

Ithiphu: Hlala ubheka amashadi ahambisanayo ukuze ugweme amaphutha abizayo futhi uqinisekise ukuxhumana okuhlala isikhathi eside.

Ukuqinisekisa Umthamo Ofanele Womthwalo

Okungalungileukulayisha umthamo wokukhethwakuyiphutha elivamile elibeka engcupheni ukuphepha nokusebenza kwemishini. Amabhawodi e-Hex namantongomane kufanele amelane namandla asetshenziswa ngesikhathi sokusebenza ngaphandle kokukhubazeka noma ukwehluleka. Ukukhetha izinsimbi ezinobufakazi obunganele noma amandla aqinile kungaholela ekuhlulekeni okuyinhlekelele.

Ochwepheshe kufanele:

- Bala ubukhulu bezidingo zomthwalo wohlelo lokusebenza.

- Bheka amazinga omkhakha, njenge-ASTM noma i-ISO, ukuze uthole izilinganiso zomthwalo.

- Khetha izixhumi ezinomkhawulo wokuphepha ukuze uphendule ngezingcindezi ezingalindelekile.

Qaphela: Izixhumi ezilayisha kakhulu zingabangela ukukhumula intambo noma ukunwetshwa kwebhawodi, kwehlise ukuzinza kukonke koxhumo.

Ukubalwa Kwezici Zemvelo

Ukungazinaki izimo zemvelo ngesikhathi sokukhetha into yokubopha kungabangela ukugqwala, amandla ancishisiwe, noma ukwehluleka komshini. Izingosi zokwakha zivame ukuchaya izibophelelo kumswakama, amakhemikhali, nokuguquguquka kwezinga lokushisa, okungahle kulimaze izinto ngokuhamba kwesikhathi.

Ukubhekana nezici zemvelo:

- Sebenzisa ama-coatings amelana nokugqwala, okufana nokufaka i-galvanization noma i-zinc plating, ezimeni ezinomswakama noma ezimanzi.

- Khetha insimbi engagqwali noma i-alloy steel ngezinga lokushisa eliphezulu noma izindawo ezinolaka lwamakhemikhali.

- Hlola njalo izinto zokubopha ukuze uthole izimpawu zokuguga noma ukugqwala.

Ithiphu ye-Pro: Cabangela izinselelo ezithile zemvelo zesayithi lephrojekthi ukuze uqinisekise ukuthi izixhumi zigcina ukusebenza kwazo nokuphila isikhathi eside.

Ukukhetha ibhawudi elilungile le-hex namantongomane kubalulekile ukuze kuqinisekiswe impilo ende nokusebenza kwemishini yokwakha. Impahla, amandla, usayizi, ama-coatings, nezindleko konke kudlala indima ebalulekile ekunqumeni ukwethembeka kwezinsimbi. Izibophelelo zekhwalithi ephezulu azigcini nje ngokuthuthukisa ubuqotho besakhiwo kodwa futhi zinciphisa izidingo zokunakekela kanye nesikhathi sokuphumula sokusebenza.

- Imakethe ye-fasteners yezimboni kulindeleke ukuthi idlule ku-USD 125 billion ngo-2029, okubonisa ukubaluleka kwazo okukhulayo ekwakhiweni nasemishinini.

- Ochwepheshe batusa ukucwaningwa kwamabhuku okuvamile nokugcinwa kwezixhumi ukuze kuqinisekiswe ukusebenza kahle nokuvimbela ukwehluleka okungalindelekile.

Ngokubeka phambili ikhwalithi nokwenza izinqumo ezinolwazi, ochwepheshe bangakhuphula ukusebenza kahle kwemishini futhi banciphise ukuphazamiseka okumba eqolo.

FAQ

Iyiphi impahla engcono kakhulu ye-hex bolt ekwakhiweni kwangaphandle?

Insimbi engagqwali iyisinqumo esingcono kakhulu sokwakhiwa kwangaphandle. Ukumelana nokugqwala kwayo kuqinisekisa ukuqina ezimeni ezinomswakama noma ezimanzi. Kumaphrojekthi angezwani nezindleko, i-carbon steel enezingubo zokuvikela ezifana nokufaka uthayela nayo ingasebenza kahle.

Ochwepheshe bangaqinisekisa kanjani ukuhambisana okufanele kwebhawodi namantongomane?

Ochwepheshe kufanele bafanise izinto zokwakha, ukuphakama kwentambo, kanye nokucaciswa kosayizi. Ukusebenzisa amathuluzi afana nama-caliper nama-thread gauges kuqinisekisa izilinganiso ezinembile. Ukubonisana nezincomo zomkhiqizi nakho kusiza ukugwema ukungafani.

Kungani ama-coatings abalulekile kumabhawodi e-hex namantongomane?

Ama-coatings avikela izinsimbi ekugqwaleni, andise ubude bazo bempilo. I-Zinc Plating, i-galvanization, ne-phosphate coatings inikeza amazinga ahlukene okuvikela. Okukhethwa kukho kuncike ekuvezweni kwemvelo kanye nezidingo zohlelo lokusebenza.

Izinto zokubopha kufanele zihlolwe kangaki?

Izinto zokubopha kufanele zihlolwe njalo, ikakhulukazi ezindaweni ezinokucindezeleka okukhulu noma ezonakalisayo. Ukuhlola kwanyanga zonke kwezimpawu zokuguga, ukugqwala, noma ukuxega kusiza ukugcina ukuphepha nokusebenza kwemishini.

Ingabe izinsimbi eziqinile ziyadingeka kuzo zonke izicelo zokwakha?

Izibophelelo zamandla aphezulu zibalulekile emithwalweni esindayo noma ezimeni ezimbi kakhulu, njengokuxhunywa kwensimbi yesakhiwo noma imishini esindayo. Kuzinhlelo zokusebenza ezilula, izinsimbi zebanga elijwayelekile zingase zanele, inqobo nje uma zihlangabezana nezidingo zokulayisha.

Isikhathi sokuthumela: Apr-25-2025