Amandla aphezuluithrekhi ibhawudi namantongomaneama-assemblies adlala indima ebalulekile ekugcineni ukuzinza kanye nokusebenza kwamakalishi angaphansi. Ezimayini zethusi zaseChile, landelela izinhlelo zebhawodi namantongomane, kanjaloingxenye yebhawudi namantongomaneinhlanganisela, ubekezelele ukucindezeleka okukhulu, ngokuvamile edinga ukushintshwa njalo ngamahora angu-800-1,200. Ngaphezu kwalokho,lima ibhawodi namantongomaneizixazululo zibalulekile ekusetshenzisweni kwemishini enzima ehlukahlukene. I-European Machinery Directive 2023 igunyaza ukuhlolwa kwe-ultrasonic ukuze kuthuthukiswe ukuphepha, kugqamisa isidingo esibalulekile sezinsimbi ezinokwethenjelwa ekusebenzeni kanzima.

Okuthathwayo Okubalulekile

- Amabhawodi ethrekhi aqinile namantongomanezibalulekile kumakhareshi angaphansi. Bagcina amathrekhi endaweni, ukusiza imishini ukuthi isebenze kahle ezindaweni ezinzima.

- Ukuhlola amabhawodi ethrekhi namantongomane ngokuvamile kungabona umonakalo kusenesikhathi. Ukulungisa izinkinga kusenesikhathi kugwema ukulungisa okubizayo futhi kugcina okokusebenza kusebenza kangcono.

- Ukusebenzisaizinto eziqinile zamabhawodifuthi amantongomane ehlisa izindleko zokulungisa. Izingxenye eziqinile zihlala isikhathi eside, ngakho-ke uyazishintsha kancane, wonga imali nesikhathi.

Ukuqonda ama-Crawler Undercarriages

Uhlolojikelele lwe-Crawler Undercarriages

Amakalishi angaphansi kwama-crawler akha isisekelo semishini esindayo, evumela ukunyakaza okusebenzayo ezindaweni ezimazombezombe. Lezi zinhlelo zihlanganisa amathrekhi, amarola, nezinye izingxenye eziklanyelwe ukusabalalisa isisindo ngokulinganayo nokugcina uzinzo. Intuthuko yakamuva emakethe ye-undercarriage ye-crawler igqamisa ukwamukelwa kwezinto ezingasindi njengensimbi enamandla amakhulu nama-polymer athuthukile. Lezi zinto ezintsha zithuthukisa ukuqina nokusebenza kahle kukaphethiloli, okuvumela imishini ukuthi isebenze ngempumelelo ezindaweni eziyinselele. Ukwengeza, ukuhlanganiswa kwezinzwa ze-IoT zokuqapha ngesikhathi sangempela kubonisa ukushintshela emshinini ohlakaniphile, osebenza kahle kakhulu. Lo mkhuba ubonakala ikakhulukazi ezifundeni ezisathuthuka njenge-Asia-Pacific, lapho ukutshalwa kwezimali kwengqalasizinda kuqhuba isidingo semishini ethembekile.

Izingxenye Eziyinhloko kanye Nemisebenzi Yazo

Izinqola zangaphansi ze-Crawler zithembele ezingxenyeni ezimbalwa ezibalulekile ukuze kuqinisekiswe ukusebenza kahle:

- Amathrekhi: Lokhu kunikeza ukudonsa nokusekelwa, okwenza imishini ikwazi ukunqamula izindawo ezingalingani.

- Ama-Roller nama-Idlers: Lezi ziqondisa futhi zisekele amathrekhi, ziqinisekisa ukusebenza kahle nokuhleleka ngendlela efanele.

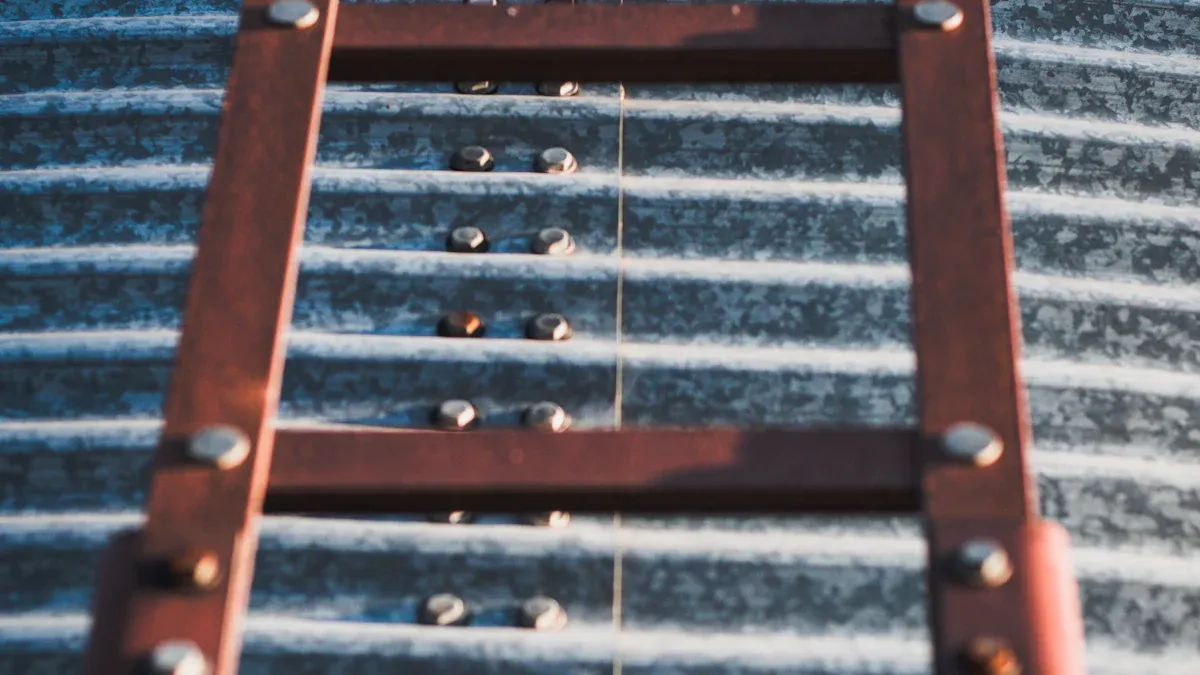

- Landelela i-Bolt and Nut Assemblies: Lezi zivikela amathrekhi kunqola yangaphansi, zigcina ubuqotho besakhiwo ngaphansi kwemithwalo esindayo.

- Drive Sprockets: Lawa mandla okudlulisa ukusuka enjini ukuya kumathrekhi, aqhubekisela phambili imishini.

Amathrendi okwenza ngokwezifiso embonini agcizelela izixazululo eziklanyelwe ukuhlangabezana nezidingo ezithile zokusebenza. Isibonelo, ukuhlolwa okukhethekile kokuvumelana nezimo kwemvelo kuqinisekisa ukuthi izingxenye zisebenza ngokuthembekile emazingeni okushisa adlulele noma ezimeni ezigqwalile. Izinqubo zokuhlola nokuhlola, ezinjengokuhlaziywa komkhondo wokugqokwa nokuqinisekiswa kokusebenza kokuvalwa, zithuthukisa futhi ukuqina nokusebenza kahle kwalezi zinhlelo. Ngokuthobela izindinganiso zomkhakha ezifana ne-ISO 6014, abakhiqizi baqinisekisa ukuthi amakalishi angaphansi ahlangabezana nezilinganiso zokusebenza eziqinile.

Iqhaza Le-Track Bolt kanye Namantongomane ku-Crawler Undercarriages

Ukuqinisekisa Ukuzinza kanye Nobuqotho Besakhiwo

Landelela amabhawodi namantongomaneisebenza njengomgogodla wezinqola zangaphansi ezikhasayo. Lezi zingxenye zivikela amathrekhi kuhlaka lwe-undercariage, zivimbela ukugudluzwa ngesikhathi sokusebenza. Imishini enzima ivamise ukusebenza ezindaweni lapho indawo engalingani namandla anomthelela omkhulu inselele ukuzinza kwesakhiwo. Ngaphandle kwama-fasteners athembekile, amathrekhi angaxegisa noma aphume, onakalise amandla omshini okusebenza ngokuphepha nangempumelelo.

Abakhiqizi baklama amabhawodi ethrekhi namantongomane ukuze amelane nengcindezi enkulu nokudlidliza. Izinto zamandla aphezulu, njengensimbi ye-alloy, ziqinisekisa ukuthi lezi zibophelelo zigcina ubuqotho bazo ngaphansi kwemithwalo esindayo. Ubunjiniyela obunembayo buphinde buthuthukise ukusebenza kwabo, bubavumele ukuthi bamelane nokuguga nokuguqulwa ngokuhamba kwesikhathi.

Ithiphu:Ukuhlolwa okuvamile kwamabhawodi ethrekhi namantongomane kungasiza ekuboneni izimpawu zokuqala zokuguga noma zokonakala, kuqinisekiswe ukushintshwa okufika ngesikhathi nokuvimbela ukuwohloka okumba eqolo.

Igalelo Ekusabalaliseni Komthwalo Nokuqondanisa

Amabhawodi ethrekhi namantongomane adlala indima ebalulekile ekusabalaliseni isisindo ngokulinganayo kuyo yonke inqola yangaphansi. Ukusatshalaliswa komthwalo ngendlela efanele kunciphisa ingcindezi ezingxenyeni ezithile zomuntu ngamunye, kwandise isikhathi sazo sokuphila futhi kunciphisa ingozi yokwehluleka kwemishini. Ngokuvikela amathrekhi ngokuqinile, lezi zibophelelo ziqinisekisa ukuthi umshini ugcina ukuqondanisa okuhle ngesikhathi sokusebenza.

Amathrekhi angacaciswanga kahle angaholela ekugugeni okungalingani, ukunciphisa ukusebenza kahle, kanye nokwenyuka kokusetshenziswa kukaphethiloli. Amabhawodi ethrekhi namantongomane avimbela izinkinga ezinjalo ngokugcina amathrekhi endaweni yawo ehlosiwe. Lokhu kuqondanisa kubaluleke kakhulu ezinhlelweni ezifana nezimayini nokwakha, lapho imishini kufanele ihambe ezindaweni eziyinselele ngenkathi ithwele imithwalo esindayo.

I-track bolt nesistimu yamantongomane enakekelwa kahle inikela ekusebenzeni okushelelayo nokusebenza okuthuthukisiwe. Abasebenzisi bangathembela emishinini yabo ukuthi isingathe imisebenzi enzima ngaphandle kweziphazamiso, ithuthukise ukukhiqiza nokuphepha endaweni yomsebenzi.

Ukubaluleka Kwezinto Ezinamandla Aphezulu Kumabhawodi Wethrekhi Namantongomane

Ukumelana Nemithwalo Enzima Nengcindezi

Izinto ezisezingeni eliphezulukumabhawodi ethrekhi namantongomane kubalulekile ekusingatheni imithwalo emikhulu kanye nezingcindezi okuhlangabezana nazo ekusebenzeni kwemishini esindayo. Lezi zibophelelo kufanele zibekezelele ukucindezela okuqhubekayo okuvela ezindaweni ezingalingani, ukudlidliza, nesisindo semishini ngokwayo. Ukuhlolwa kwaselabhorethri kuqinisekisa amandla abo okumelana namandla anjalo ngokuhlolwa okuqinile.

| Uhlobo Lokuhlola | Incazelo |

|---|---|

| Ukuhlolwa Komshini | Kufaka phakathi ukuhlolwa kobufakazi bomthwalo, ukuhlolwa kwe-tensile, nokuhlolwa kokuqina (i-Rockwell, i-Brinell, njll.) |

| Ukuhlolwa kweMetallurgical | Kubandakanya ukuhlolwa kokuqina okuncane, ukuhlolwa kwe-microstructural, nophenyo lokwehluleka kwensimbi |

| Ukuhlaziywa Kwamakhemikhali | Ihlanganisa i-ICP/OES kanye nokuhlaziywa kwe-Spark OES ukuze kuhlolwe ukwakheka kwezinto ezibonakalayo kanye nezakhiwo |

Lezi zivivinyo ziqinisekisa lokholandelela amabhawodi namantongomaneukuhlangabezana nezindinganiso zemboni zamandla nokwethembeka. Ukuhlolwa okuvamile kwezinsimbi nezinto zokusetshenziswa kuqinisekisa ukufaneleka kwazo ezindaweni ezidinga kakhulu. Ukuhlolwa kwe-bolt futhi kuqinisekisa ukuthi lezi zingxenye zingamelana nomthwalo wazo omisiwe futhi zisebenze ngempumelelo ngaphansi kwengcindezi yokusebenza.

Ukuqina Ezimweni Eziqinile

Amabhawodi ethrekhi namantongomane kufanele asebenze ngokwethembeka ezimeni ezimbi kakhulu, okuhlanganisa izinga lokushisa eliphezulu, indawo ebolayo, kanye nokuchayeka njalo kumandla angaphandle. Ukuhlolwa kwenkundla nokuhlolwa kwemvelo kubonisa ukuqina kwazo kuzilungiselelo ezinjalo.

- Ukuhlolwa kwe-torque okukhona kuhlola ukuthi izixhumi zimelana ngempumelelo kangakanani nokuxegiswa ngenxa yokudlidliza namandla angaphandle.

- Lokhu kuhlola kubalulekile ezimbonini ezifana ne-nuclear, i-aerospace, nezasolwandle, lapho ubuqotho be-fastener kuvimbela ukwehluleka okuyinhlekelele.

- Imiphumela evela kulokhu kuhlola iqinisekisa ukuthi amabhawodi ethrekhi namantongomane ahlangabezana namazinga aphansi okusebenza okuhlosiwe, okunciphisa amaphutha futhi athuthukisa ukuqina.

Ngokumelana nokuguga nokuxegiswa, izinto ezisebenza ngamandla amakhulu zinweba isikhathi sokuphila se-track bolt namantongomane. Lokhu kuqina kunciphisa izidingo zokunakekelwa futhi kuqinisekisa ukuthi imishini isebenza ngokuphepha nangempumelelo ezindaweni eziyinselele.

Izinzuzo zamabhawodi wethrekhi yamandla aphezulu namantongomane

Ukuphepha Okuthuthukisiwe Nokwethenjelwa

Amabhawodi ethrekhi anamandla aphezulu namantongomanekuthuthukisa kakhulu ukuphepha nokuthembeka kwezimoto zangaphansi ezikhasayo. Lezi zingxenye ziqinisekisa ukuthi amathrekhi ahlala eboshwe ngokuvikelekile, ngisho nangaphansi kwezimo zokusebenza ezinzima. Ngokuvimbela ukususwa kwethrekhi noma ukuhlukaniswa, banciphisa ubungozi bezingozi nokungasebenzi kwemishini.

Ukusetshenziswa kwezinto ezithuthukisiwe, njengensimbi ye-alloy, kunikeza ukumelana okukhethekile nokucindezeleka nokudlidliza. Lokhu kuqina kuqinisekisa ukuthi izinsimbi zigcina ubuqotho bazo ngokuhamba kwesikhathi, ngisho nasezindaweni ezinomthelela omkhulu njengeziza zokwakha noma imisebenzi yezimayini. Abaqhubi bangathemba ukuthi imishini yabo izosebenza ngokungaguquki, bazi ukuthi i-track bolt namantongomane ahlanganisayo aklanyelwe ukuphatha imisebenzi enzima.

Qaphela:Ukuhlolwa okuvamile nokuhlolwa kwetorque kuqhubekela phambili kuthuthukisa ukuphepha ngokuhlonza izinkinga ezingaba khona ngaphambi kokuba zidlulele ekubeni ukwehluleka okubalulekile.

Ukuphila Okude Kwezingxenye Ze-Undercarriage

Amabhawodi ethrekhi anamandla aphezulu namantongomane anikela enkathini yokuphila enwetshiwe yezingxenye zokuthwala ngaphansi kwekalishi. Ngokugcina amathrekhi ngokuqinile, anciphisa ukunyakaza okungadingekile futhi aguge ezingxenyeni eziseduze, njengama-roller, ama-idlers, nama-sprocket. Lokhu kuzinza kunciphisa ubunzima ezingxenyeni ezingazodwana, kuzivumela ukuthi zisebenze kahle isikhathi eside.

Ukusatshalaliswa komthwalo ngendlela efanele, okwenziwa yilezi zibophelelo, nakho kudlala indima ebalulekile ekulondolozeni inqola yangaphansi. Ukusatshalaliswa kwesisindo esingalingani kungaholela ekugugeni ngaphambi kwesikhathi, kodwa amabhawudi namantongomane ekhwalithi ephezulu aqinisekisa ukuthi umthwalo usakazwa ngokulinganayo kulo lonke uhlelo. Le bhalansi ayigcini nje ngokuthuthukisa ukusebenza kodwa futhi ibambezela isidingo sokushintshwa okubizayo.

Abakhiqizi bavame ukutusa ukusebenzisa izibophelelo ezihlangabezana nezindinganiso zomkhakha ukuze kukhuliswe ukuqina kwayo yonke inhlangano ye-undercarriage. Ukutshala imali kuizingxenye eziphezulu zamandlaekugcineni konga isikhathi nezinsiza ngokunciphisa imvamisa yokulungisa.

Izindleko Zokulungisa Eziphansi kanye Nesikhathi Sokuphumula

Ukusebenzisa ama-bolt namantongomane ethrekhi enamandla amakhulu kungehlisa kakhulu izindleko zokulungisa futhi kunciphise isikhathi sokuphumula. Lezi zibophelelo zenzelwe ukumelana nezimo ezinzima, zinciphisa amathuba okuhluleka okungalindelekile. Ngenxa yalokho, opharetha bachitha isikhathi esincane bekhuluma ngezinkinga zemishini kanye nesikhathi esiningi begxile emisebenzini ekhiqizayo.

Ukuqina kwalezi zingxenye kuphinde kuhumushe ekushintshweni okumbalwa, okwehlisa izindleko zokunakekela sezizonke. Ezimbonini ezinjengezimayini nezokwakha, lapho ukuphelelwa yisikhathi kwemishini kungaholela ekulahlekelweni okukhulu kwezimali, lokhu kwethembeka kubaluleke kakhulu.

Ithiphu:Ukusebenzisa ishejuli yokulungisa esebenzayo ehlanganisa ukuhlolwa okuvamile kwamabhawodi wethrekhi namantongomane kungaqhubeka nokunciphisa isikhathi sokuphumula futhi kuqinisekise ukusebenza kahle.

Ngokukhetha izinsimbi eziqinile, amabhizinisi angafinyelela ibhalansi phakathi kokusebenza kahle nokusebenza kahle kwezindleko. Lokhu kutshalwa kwezimali akugcini nje ngokuthuthukisa ukusebenza kwamakalishi angaphansi kodwa futhi kusekela inzuzo yesikhathi eside.

Ukukhetha Nokugcina Amabhawodi Wethrekhi Namantongomane

Izinto Okumele Zicatshangelwe Lapho Ukhetha Amabhawodi Amandla Aphakeme Namantongomane

Ukukhetha amabhawodi anamandla aphezulu namantongomane kubalulekile ukuze uqinisekise ukusebenza nokuphepha kwamakalishi angaphansi. Imibandela ethile yobuchwepheshe kanye namazinga emboni aqondisa le nqubo:

- Ukukhetha Okubalulekile: Khetha izinto ezifana nensimbi, insimbi engagqwali, noma i-alloy steel ukuze uzuzeamandla aphezulukanye nokuqina.

- Izinketho zokumboza: Sebenzisa okokunamathela okufana nezinc plating noma uthayela ukuthuthukisa ukumelana nokugqwala, ikakhulukazi ezindaweni ezinokhahlo.

- Usayizi Nohlobo: Qinisekisa uhlobo lwe-fastener nosayizi kuqondaniswe nohlelo lokusebenza, ubhekisela kumazinga we-ASTM fastener ukuze uthole ukunemba.

- Izici Zokusebenza Eziyinhloko: Cabangela ububanzi bebhawodi, idigri yokuzenzisa, namandla aqinile, njengoba lokhu kuba nomthelela omkhulu ekusebenzeni kwe-shear namandla okulayisha.

- Izimo Zemvelo: Linganisa izici ezifana nezinga lokushisa, ingcindezi, nokugqwala ukuze uqinisekise ukuthi izibophelelo zingakwazi ukumelana nezinselele zokusebenza.

Izindlela zokufaka ezifanele nazo zidlala indima ebalulekile ekwandiseni ukusebenza kahle kwe-track bolt namantongomane. Isibonelo, ukusebenzisa amantongomane aphindwe kabili noma ukuqinisa intwasahlobo kungasiza ukulawula ukulahleka kokuzenzisa, ukuthuthukisa ukuthembeka kwesikhathi eside.

Amathiphu Okulungisa Ukusebenza Okulungile

Izinqubo zokulungisa ezisebenzayo zibalulekile ekuthuthukiseni ukusebenza nempilo ye-track bolt namantongomane. Ukuhlola okuvamile kanye nezinyathelo ezisebenzayo kungavimbela ukwehluleka okubizayo. Amathiphu okunakekela abalulekile ahlanganisa:

- Hlela Ukuhlola Okuvamile: Hlola izinto zokubopha ukuze uthole izimpawu zokuguga, ukugqwala, noma ukuxega.

- Gcina Amarekhodi anemininingwane: Gcina amalogi emisebenzi yokulungisa ukuze ulandelele amathrendi okusebenza futhi uhlonze izinkinga ezivelayo.

- Nika amandla ama-Opharetha: Qeqesha o-opharetha ukuthi babone izimpawu eziyisixwayiso zangaphambi kwesikhathi zokwehluleka kweziqinisi, njengokudlidliza okungajwayelekile noma ukungahambi kahle.

- Sebenzisa ubuchwepheshe: Sebenzisa isofthiwe yokulungisa izimoto noma izibalo ze-CMMS ukuze uqaphe ukusebenza kwe-fastener futhi ulungise amashejuli okulungisa ngokufanele.

- Tshala Kumathuluzi Ahlakaniphile: Sebenzisa ama-torque wrenches namanye amathuluzi anembayo ukuze uqinisekise ukuqiniswa okufanele ngesikhathi sokufakwa nokugcinwa.

Amasu okuvikela okulondoloza, afana Nokuphathwa Kokusebenza Kwempahla (APM), agcizelela ukuqoqwa kwedatha nokuhlaziya okubikezelwayo. Lezi zindlela zisiza ukuhlonza ukungasebenzi kanye nokuthuthukisa amashejuli okunakekela, ukuqinisekisa ukuthi amakalishi angaphansi asebenza ngokuphepha nangempumelelo.

Ithiphu: Amawasha angaphansi kwenqola azenzakalelayo anganciphisa isikhathi sokunakekela futhi athuthukise ukukhiqiza ngokuqeda imisebenzi yokuhlanza okwenziwa ngesandla.

Amabhawudi ethrekhi anamandla aphezulu namantongomane abalulekile ekuqinisekiseni ukuphepha, ukuqina, nokusebenza kahle kwamakalishi angaphansi. Iqhaza labo ekugcineni ubuqotho besakhiwo kanye nokwehliswa kwezindleko zokunakekelwa akukwazi ukweqiwa.

Ukutshala imali kuizinsimbi zekhwalithi ye-premiumithuthukisa ukusebenza kwemishini futhi inciphise isikhathi sokuphumula, inikeze ukonga kwezindleko zesikhathi eside nokuthembeka kokusebenza. Khetha ngokuhlakanipha ukuze uthole imiphumela ehlala njalo.

FAQ

Yini eyenza amabhawudi namantongomane ethrekhi ephezulu ahluke kuzibopheli ezijwayelekile?

Amabhawodi ethrekhi anamandla aphezulu namantongomanesebenzisa izinto eziphambili njengensimbi ye-alloy. Zimelana nemithwalo esindayo, ukudlidliza, kanye nengcindezi yendawo ezungezile, okuqinisekisa ukuqina nokwethembeka ezinhlelweni ezifunwayo.

Kufanele kuhlolwe kangaki amabhawodi namantongomane ethrekhi?

Hlolalandelela amabhawodi namantongomanenjalo ngamahora okusebenza angama-500-1,000. Ukuhlola okuvamile kusiza ukuhlonza ukuguga, ukugqwala, noma ukuxega, ukuvimbela ukwehluleka okungalindelekile kanye nesikhathi sokuphumula esibizayo.

Ingabe amabhawodi namantongomane anamandla amakhulu anganciphisa izindleko zokunakekela?

Yebo, ukuqina kwazo kunciphisa ukushintshwa nokulungiswa. Lokhu kwethembeka kunciphisa izindleko zokulungisa kanye nokuphazamiseka kokusebenza, ikakhulukazi ezimbonini ezifana nezimayini nezokwakha.

Isikhathi sokuthumela: Apr-27-2025